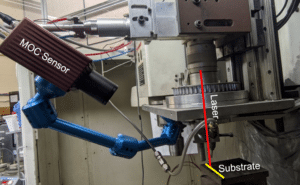

Gas metal arc welding (GMAW) is one of the most common welding techniques. In the GMAW process, an electric arc is formed between the metal and a wire electrode, applying heat to the metal pieces. This action melts and fuses the parts together to form a permanent bond. Since GMAW represents a large market share of high temperature applications, it is desirable to extend the applications of the MOC system to include GMAW.

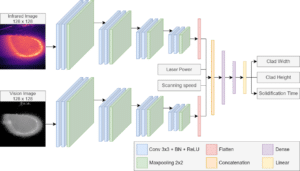

Below are the thermal video and visible light video captured during GMAW.

These videos demonstrate the quality of images recorded by the MOC sensor during GMAW. The weld bead is visible in both wavelengths, and though the arc obstructs the melt pool the solid portion of the bead is visible, which is sufficient for geometry and microstructure predictions.

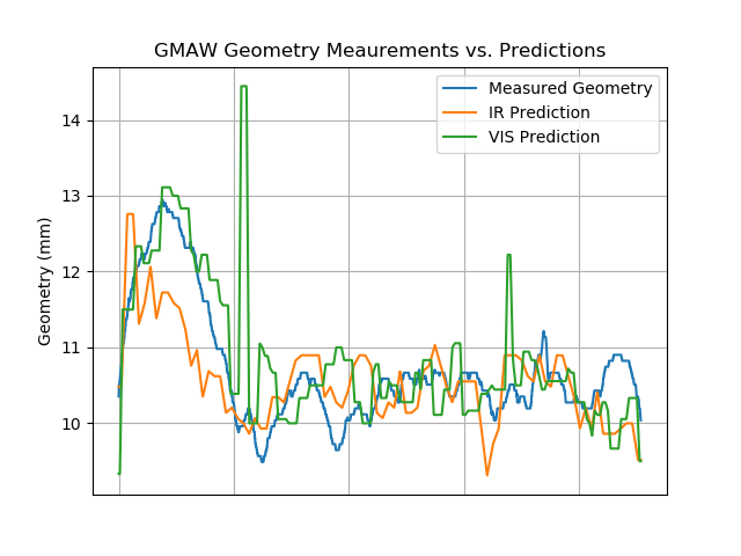

As seen in the image below, the width of the weld bead can be estimated in real-time with the vision images. The outliers in the predicted geometry can be reduced in future geometry predictions since this estimation is only on preliminary testing. Future geometry predictions may be improved by changes in camera settings and in the prediction algorithm.

These preliminary geometry predictions and the quality of videos captured during GMAW demonstrate the potential for the MOC system to be used in welding applications. With improvements to the software and potentially changing the camera settings, the applications of the MOC system can be expanded to include GMAW. This project also highlights the versatility of the MOC system, showing that both GMAW and direct energy deposition can be optimized with the MOC system, and other high temperature manufacturing processes may benefit from the MOC system as well.