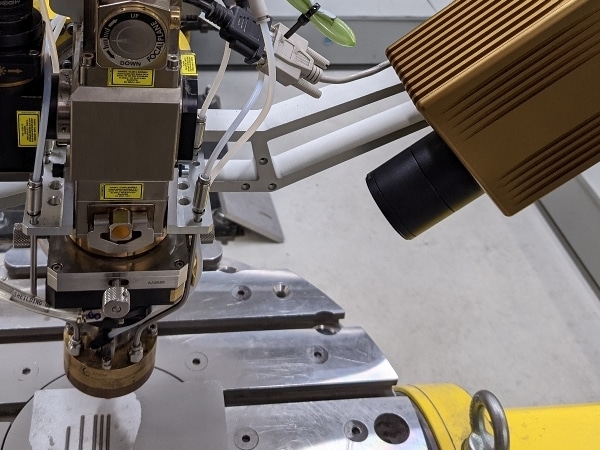

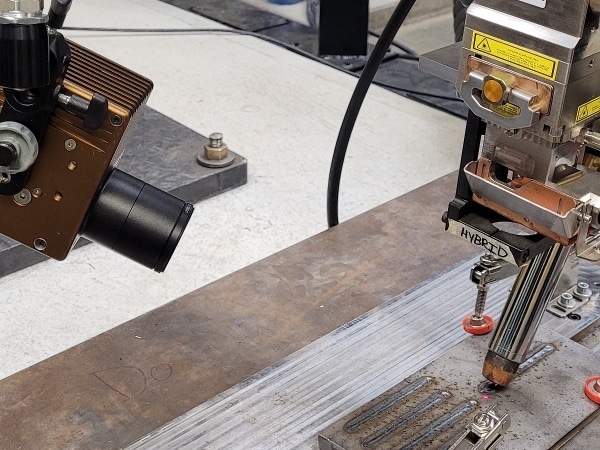

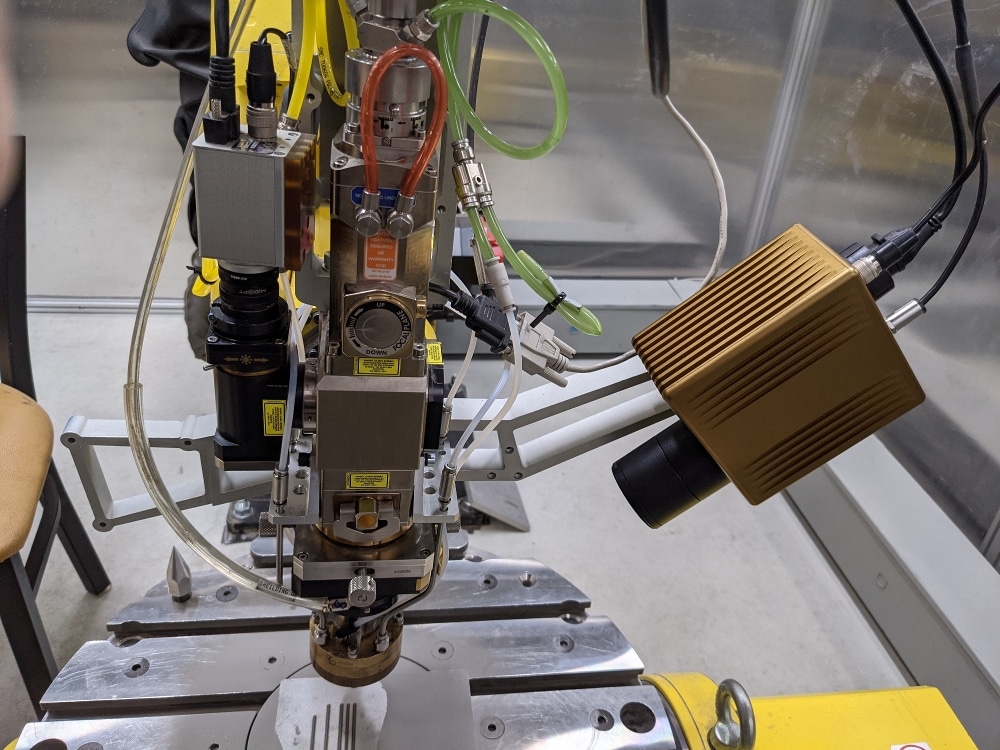

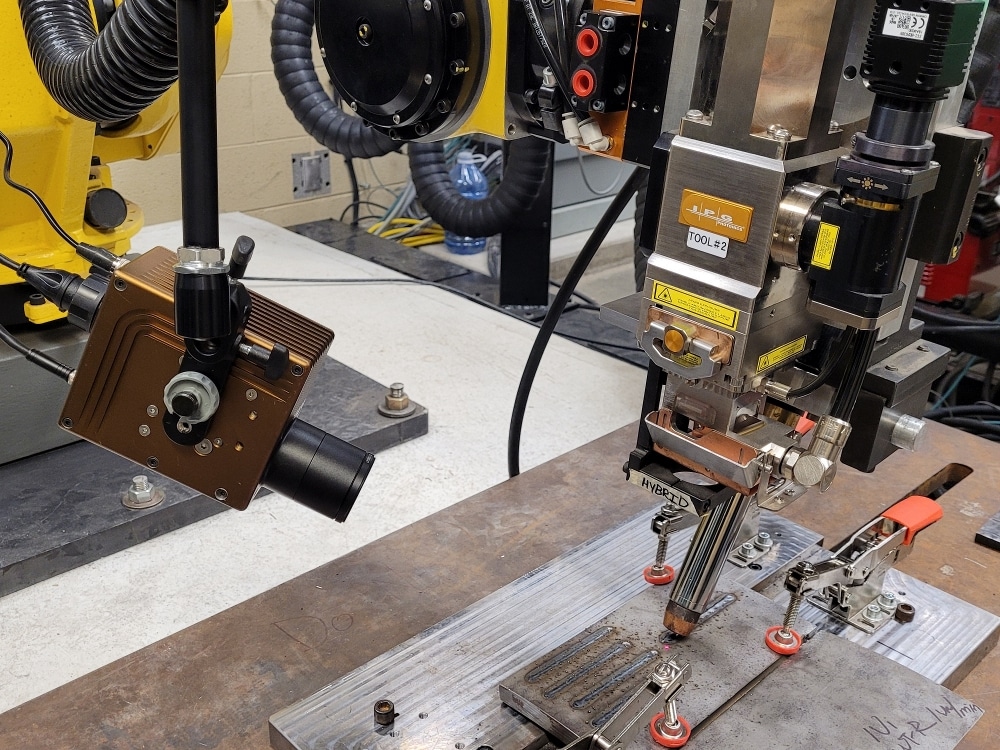

Easy installation and calibration without any modification to your machine

Real-time process monitoring that provide invaluable process information

Analyze and augmentate recorded process data for rapid process optimization

Produce consistent geometry and microstructure with real-time process control

During LAM our system is able to monitor the melt pool to estimate the geometry and material properties of the clad in reatime, thus reducing the initial testing investment. Moreover, implementing control allows us to update the laser power and scanning speed in real time to ensure the material properties are consistent during manufacturing.

In welding, we are able to monitor the weld bead in real time to guarantee the quality of the weld, furthermore, monitoring the size and shape of the arc provides more details of the process as well. Controlling the power in real time can be used to compensate for complex geometry of workpieces being joined and for accumulated heat.